Search This Supplers Products:GEOMEMBRANEPACKAGING MACHINEBIODEGRADABLE BAGHDPE LINERFILLING MACHINESEALING MACHINE

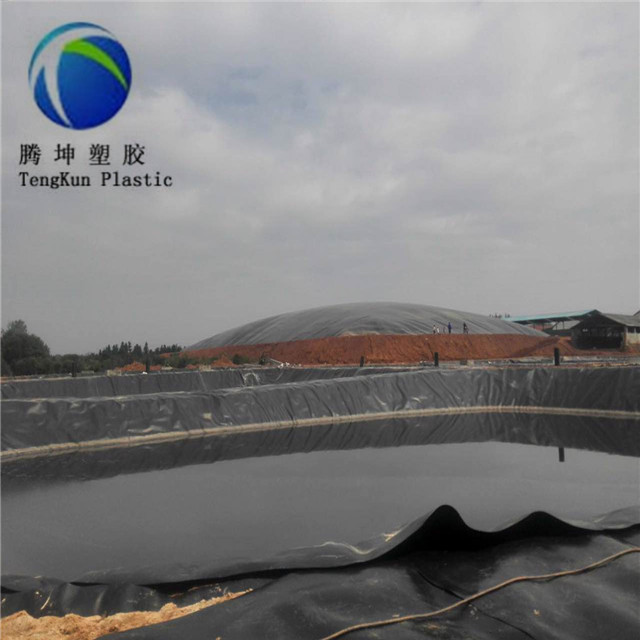

I want to use geomembrane as a fish pond. How to use geomembrane construction method is the best?

sourceProduct news

publisherTina Zhang

time2018/06/22

- The bottoms and walls of the fish ponds should be leveled and then laid with geomembrane. The joints should be reserved 6 to 10 cm. Welded with geomembrane welding machine.

Geomembrane welding matters:

Welder welding machine welding process is divided into: adjustment pressure set temperature set speed weld lap inspection film loading machine start motor pressure welding.

Joints shall not contain oil and dust. The overlapping section of HDPE geomembrane shall not contain any debris or other debris. When there is any debris, it must be cleaned before welding.

Every day when the welding begins, a 0.9mm x 0.3mm test piece must be first welded on site, the lap width should be no less than 10cm, and the peeling and shear test should be conducted on site with a tensile machine. After the sample is qualified, it can be adjusted at that time. Velocity, pressure, and temperature are exactly what is welded. The date, time, and ambient temperature must be indicated on the sample. In the welding process, the hot crucible welding machine needs to pay attention to the running condition of the welding machine at any time. The speed and temperature should be fine-tuned according to the actual situation on the site.

Welds are required to be neat and beautiful, with no welding or jumping away.

When the length of geomembrane is not enough, it needs to be long-spliced. It is necessary to weld the transverse weld first and then weld the longitudinal joint. The distance between transverse welds should be greater than 50cm.

Adjacent geomembrane welds should be staggered and lapped as far as possible. The joints formed between the diaphragms should be T-shaped and cross-shaped should be reduced as much as possible. The longitudinal molds should be reinforced with welders at the intersections of the welds.